COATINGS

HOME > COATINGS

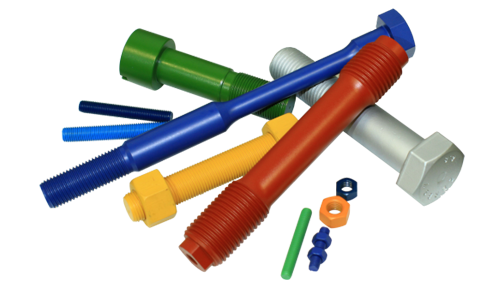

PTEE coatings (Polytetrafluoroethylene) are non-stick, fluoropolymer, high temp coatings. They have a one-coat system or a two-coat system of a primer and topcoat and have several features that make them go-to coatings.

PTFE COATING

Zinc flake coatings are non-electrolytically applied coatings, which provide good protection against corrosion.

Chromium coating is a technique that consists of electroplating a thin layer of the chemical element onto metal, to provide protection against wear and corrosion.

Zinc phosphate coating is used to protect steel and iron parts from rust and corrosion.

Manganese phosphate coatings are applied to the surface of ferrous substrates to prevent galling and to improve break-in properties.

Hot–dip galvanizing (HDG) is the process of coating fasteners by immersing it in a bath of molten zinc.

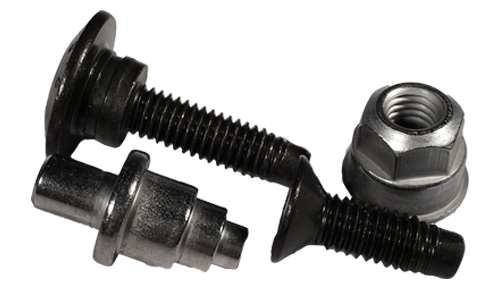

Oxidation, or Blackodising, is an application that increases the corrosion resistance of the material.

BLACKODISING

Zinc plating is an electrochemical galvanizing technique where a thin coating of zinc metal is applied to the surface of a metal object (known as the substrate).

Zinc-Nickel is normally applied for corrosionprotection purposes, and functions as a “sacrificial coating”, corroding before the base material.

Electroless Nickel Plating (ENP) is the deposit of a nickel-alloy coating by chemical reduction – without the electric current that’s used in electroplating processes.

Cadmium plating is what’s known as a sacrificial coating, meaning it corrodes and breaks down before the underlying material, adding a layer of protection to the metal below.

Nickel chrome plating is an excellent choice in applications where superior corrosion protection and wear resistance are critical.

Lead- and nickel-free anti-seize paste used to reduce wear and optimize friction of threaded fasteners